Transformer T3-100 to T3-600

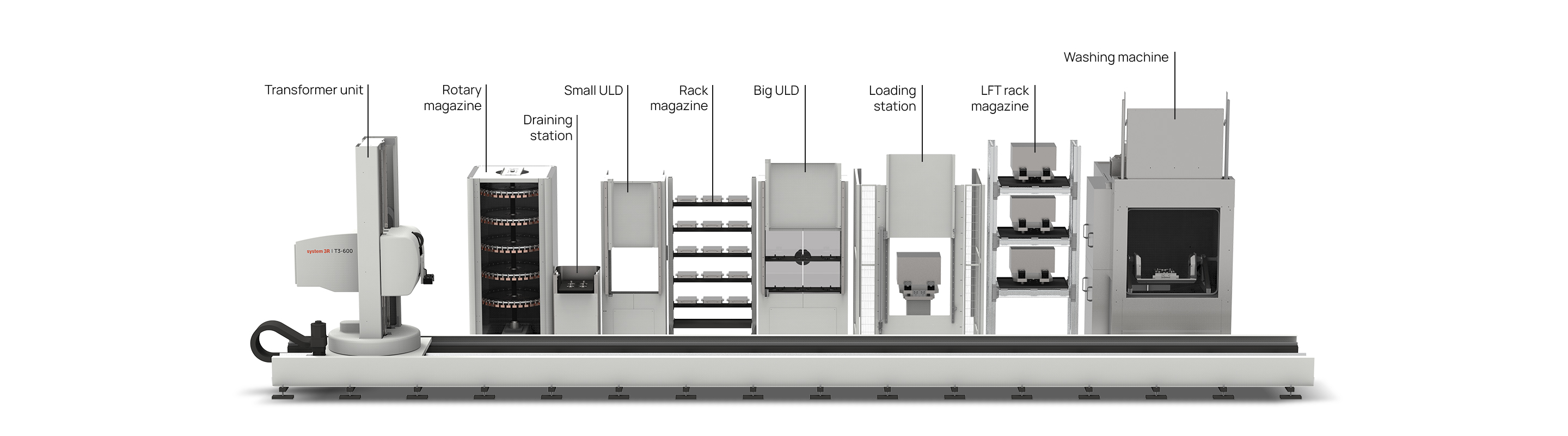

Scalable Automation solutions for various types of machines. With standardized modules allow for cost-effective yet flexible Automation. Are you ready to begin, add or extend your automation?

Please accept all cookies to view the external content.

Scalable Automation solutions for various types of machines. With standardized modules allow for cost-effective yet flexible Automation. Are you ready to begin, add or extend your automation?

Whatever the Automation requirement, the Transformer can be tailored to serve your needs : customer-specific solutions.

As with all System 3R products, its open architecture allows it to interconnect and serve different machines.

Please accept all cookies to view the external content.

Please accept all cookies to view the external content.

The Transformer T3 exist in 4 models. 100/150/200/600 kg. The T3-600 can lift and handle a Total weight of 600 kg including gripper, pallet and workpiece.

The Transformer T3 can serve All technologies like EDM,WEDM Milling,Laser,CMM,washing and grinding.

The Transformer T3 supports 5 tooling systems in the magazine. There are 20 different tooling Systems which can be prepared for in the magazine.

Prepare an extra shift and make Sure you produce 24/7. The Transformer T3 can as well be prepared for AMR support, thi to handle logistics from and to the Cell. (Autonomous Mobile Robot)

Please accept all cookies to view the external content.

Our Transformer concept is designed to handle a wide variety of tools; everything from the small Macro (54 x 54 mm) to the large DelphinBIG (800 x 800 mm). Other manufacturers’ tools can also be handled.

In each automation cell, all the machines and accessories have chucks suitable for getting pallets from the manipulator.

The automation cell’s desired storage capacity is achieved by using a suitable number of magazines and adapting the layout appropriately.

| Manipulator | |

| Payload (workpiece, pallet and gripper) | 600 kg |

| Z axis reach | 2,000 m (up to 800 mm/s) |

| Z axis reach | 1,500 m (up to 400 mm/s) |

| C axis range | 0-340 ° (up to 90 °/s) |

| Air pressure and flow | 6 bars (± 1 bar), 150 l/min |

| Power supply | Three phase (200, 230, 400 or 500 V AC |

| Frequency | 50/60 Hz ±1% |

| Power consumption | <4,0 kVA |

| External fuse | 20 Amps, type D |

| Electrical interface | RS-232 Standard - Parallel port 24V Isolated Standard - RS-422/485 option |

| Floor requirements | Concrete quality, C20/25; thickness, > 180 mm thick (for fixing through anchors); planarity, < 5 mm/m |

| Temperature | Operating temperature, +5°C to +30°C (control cabinet) |

| Humidity | RH, max. 95% |

| Noise level | < 77 dB (A) ISO/DIS 11201 |

| Rail | |

| Length | Up to 30 m |

| Number of machines | Up to 20 |

| Rail axis speed | Max. 1.2 m/s |

| Floor requirements | Concrete quality, C20/25; thickness, > 180 mm thick (for fixing through anchors); planarity, < 4 mm/m |

| Accessories | |

| Rotary magazine | Open or closed |

| Rack magazine | Full or half |

| LFT magazine | Up to 4 levels with full weight |

| Loading and preparation station | Loading pillar (small/big), Loading station (ULD small/big), indexing option, preparation option |

| AMR bay | Docking station with lifter |

| Drying station | For wire EDM (fluid blow-off and air-drying as determined by integrated functions) |

| Draining station | For EDM, with dielectric pump-back function |

| Washing machine | 1 or 2 tanks, small or big |

Magazines are available in two basic designs: rack and rotary.

Each magazine unit consists of a number of shelves (determined by the height of the workpieces in question).

| Rotary magazine |

||

| Tooling |

Positions* | Size in mm (in) |

| Dynafix |

4 5 |

320 x 320 (12.5 x 12.5) 290 x 290 (11.4 x 11.4) |

| GPS 240 |

4 5 6 |

320 x 320 (12.6 x 12.6) 290 x 290 (11.4 x 11.4) 260 x 260 (10.2 x 10.2) |

| Macro-Magnum | 8 10 12 |

210 x 210 (8.27 x 8.27) 185 x 185 (7.28 x 7.28) 160 x 160 (6.3 x 6.3) |

| GPS 120 |

12 | 160 x 160 (6.3 x 6.3) |

| Macro | 36 | 65 x 65 (2.56 x 2.56) |

| Full rack magazine |

||

| Tooling | Positions* | Size in mm (in) |

| Delphin 400x400 |

1 2 |

700 x 500 (27.56 x 19.68) 400 x 400 (15.75 x 15.75) |

| Dynafix | 1 2 |

700 x 500 (27.56 x 19.68) 400 x 400 (15.75 x 15.75) |

| GPS 240 | 2 3 |

400 x 400 (15.75 x 15.75) 275 x 275 (10.83 x 10.83) |

| Macro-Magnum | 4 5 |

210 x 210 (8.27 x 8.27) 170 x 170 (6.7 x 6.7) |

| Macro 116 | 6 | 150 x 150 (5.9 x 5.9) |

| GPS 79 | 10 | 95 x 95 (3.74 x 3.74) |

| Macro |

12 |

70 x 200 (2.75 x 12.2) |

| Half rack magazine |

||

| Tooling |

Pos.* | Size in mm (in) |

| Delphin 498 x 498 | 1 | 500 x 500 (19.68 x 19.68) |

| Dynafix |

1 |

480 x 400 (18.9 x 15.75) |

| GPS 240 |

1 |

480 x 400 (18.9 x 15.75) |

| LFT Full rack magazine |

||

| Tooling |

Pos.* | Size in mm (in) |

| Delphin | 1 2 |

850 x 800 (33.4 x 31.5) 400 x 800 (15.7 x 31.5) |

| Dynafix |

1 2 |

850 x 800 (33.4 x 31.5) 400 x 800 (15.7 x 31.5) |

| GPS 240 |

1 2 |

850 x 800 (33.4 x 31.5) 400 x 800 (15.7 x 31.5) |

| LFT half rack magazine |

||

| Tooling |

Pos.* | Size in mm (in) |

| Delphin | 1 2 |

850 x 550 (33.4 x 21.6) 500 x 500 (19.7 x 19.7) |

| Dynafix |

1 2 |

850 x 550 (33.4 x 21.6) 500 x 500 (19.7 x 19.7) |

| GPS 240 |

1 2 |

850 x 550 (33.4 x 21.6) 500 x 500 (19.7 x 19.7) |

* Positions per level. Maximum workpiece height is determined by the number of levels.

Optionally available with rotary magazines: Rapid ID scanning.

Optionally available with rack magazines: Additional shelves. Door for loading from behind.

*Rail type: Standard

**Rail type: Heavy

Please accept all cookies to view the youtube video content.

Please accept all cookies to view the youtube video content.

Please accept all cookies to view the external content.

Please accept all cookies to view the external content.